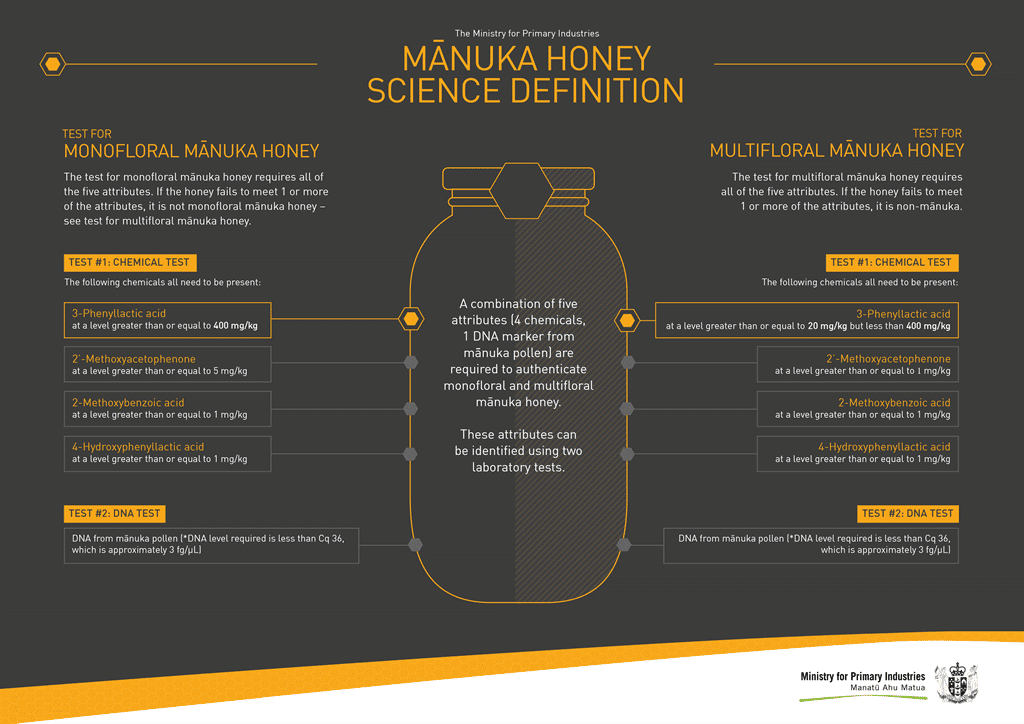

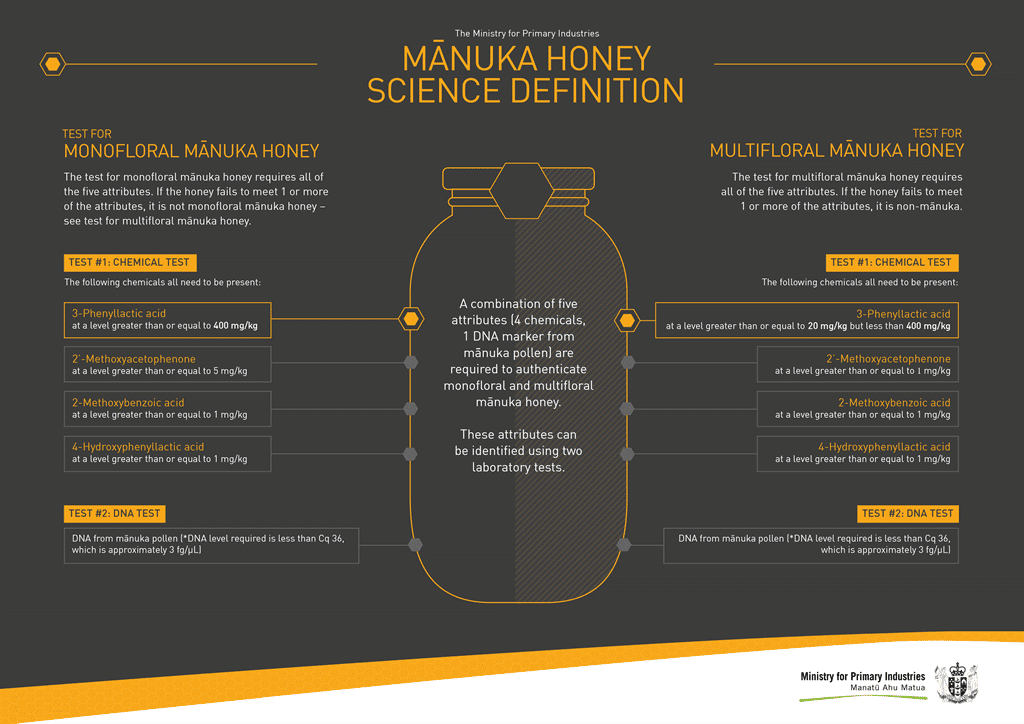

MPI (MINISTERY OF PRIMARY INDUSTRIES NZ) – DEFINITION OF MANUKA HONEY

The MPI in New Zealand has established clear guidelines to determine whether Manuka Honey is a monofloral or multifloral honey. MNZ produces only raw, monofloral MGO Manuka Honey.

MNZ’s comprehensive expertise from the beekeeping fields of New Zealand to the final product ensures the highest quality and integrity. We meticulously oversee every stage from beekeeping to production, maintaining the purity of natural ingredients and applying scientific tests to verify our products’ quality. All testing is conducted in an ISO17025 accredited IANZ laboratory. Adhering to the MPI guidelines, our RMP storage, mixing, and packaging processes ensure a controlled supply chain, from the hive right to the end product. We conduct extensive authenticity and quality tests on the honey, both in its raw form and as a final product, assuring top quality, purity, and safety. MNZ is dedicated to producing only raw, unfiltered, unpasteurized monofloral MGO Manuka Honey.

Manuka honey, a rare and special product, is made in New Zealand by bees that pollinate the native Manuka tree. This honey is produced during the brief blooming period of the Manuka trees. After collection from the honeycomb, the monofloral manuka honey undergoes rigorous quality testing. Stored at natural temperatures (below 25 degrees Celsius) to maintain its purity, the honey is then gently heated over 12 days in our honey sauna, reaching a final temperature of 35 degrees Celsius. This careful process ensures that our Manuka honey, packed in jars and labeled according to its MGO value, passes a final quality test. Our in-house control of every production phase ensures the preservation of the honey’s natural properties, resulting in exquisite raw Manuka Honey.

Monofloral Manuka honey requires meticulous attention due to its sensitivity to heat. Our testing procedures, based on MPI guidelines in New Zealand, ensure our Manuka Honey remains a true monofloral raw honey.

All our monofloral Manuka honey undergoes initial tests for five chemical compounds, as per MPI guidelines, to ensure we produce exclusively monofloral Manuka Honey. These compounds distinguish monofloral from multifloral honey.

• 3-Phenyl-lactic acid

• 2-Methoxyacetophenone

• 2-Methoxybenzoic acid

• 4-Hydroxyphenyl lactic acid

• DNA from Manuka pollen

Methylglyoxal (MGO) is another key compound rigorously tested in our labs. Professor Thomas Henle’s research identified MGO as a crucial component in Manuka honey, crucial for its unique, high-quality natural bioactivity. Testing for MGO presence is a requirement of the MPI.

Additional tests for contamination, toxins, adulteration, heat damage, and freshness include:

• Diastasis

• HydroxyMethylfurfural (HMF)

• C4 Sugars

• Aerobic Plate Count

• Escherichia coli

• Moisture content

• Tutin

• Pyrrolizidine alkaloids (PAs)

• Yeast

• Mold

• Staphylococcus aureus

• Total coliform

The MPI in New Zealand has established clear guidelines to determine whether Manuka Honey is a monofloral or multifloral honey. MNZ produces only raw, monofloral MGO Manuka Honey.